The raised floor is a system of modular elements designed for the creation of floor coverings for buildings’ indoor and outdoor spaces.

Raised Floors

This technology is extremely practical because it creates a continuous void under the floor surface that can be utilized to route all technical systems. Thanks to its usage flexibility, easy and fast installation and diverse range of coverings, it can also be applied in building renovations and can even be installed on top of existing floor coverings.

The raised floor is a lightweight dry construction system consisting of a floor surface and a support structure. The practical and functional support structure allows the removal of every single ceramic module, speeding up the inspection, modification and maintenance of the plant networks, while the system also boasts the advantages of Marazzi porcelain stoneware’s strength and aesthetic qualities.

• Rapid execution in new buildings and for building renovation projects, with immediate trafficability of the floor surface

• Flexibility for distribution and positioning of technical plant, with easily inspectable utility lines capable of simple modification post installation

• Low costs in relation to the building’s life cycle

• Design flexibility, with the possibility of altering the original project rapidly, even during the execution stage

• Maximum versatility if rooms are converted for different purposes

• Can be integrated with other technical finishing structures such as partitions and false ceilings

• High level of aesthetic personalization in both the choice of finishing material and its colours and in the ability to create designs, logos and decorative motifs on request or inserts of different materials

• Availability of a broad range of accessories for personalization of the floor

he raised floor is a technological system composed of five main elements

• supporting structure

• core

• surface layer

• perimetral edge

• backing layer

Supporting Structure

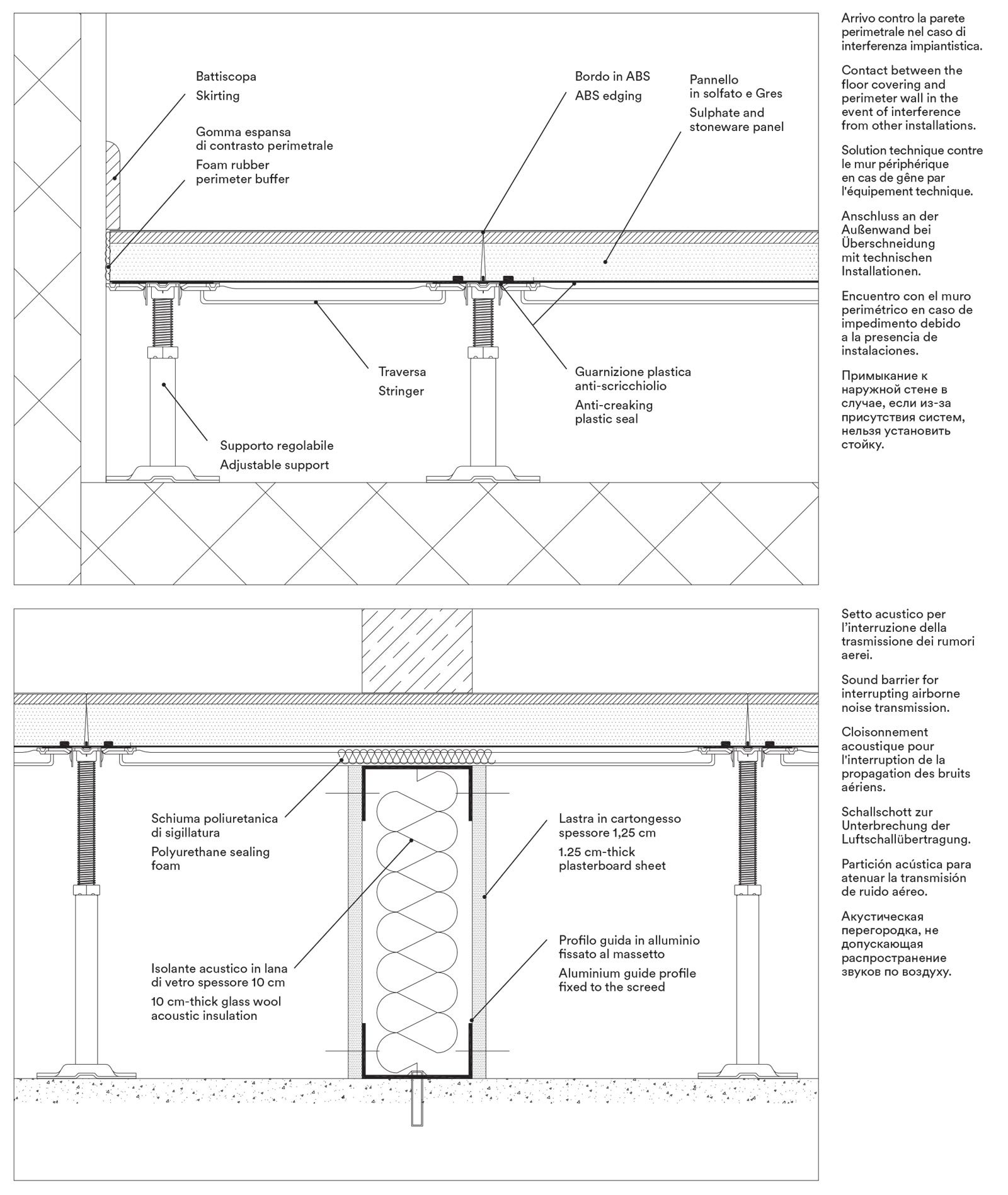

The combination of the horizontal and vertical parts supports the raised floor panel so it can be raised up higher than the building’s floor slab and be set level. The structure is in galvanized steel to prevent corrosion and consists of columns, crosspieces and gaskets

1 Pedestal: has a stem, base and head and is the vertical, load-bearing part.

2 Gaskets: fitted between the panels and the stringers are designed to reduce noise and provide an air seal.

3 Stringer: is the horizontal, modular part that links the columns and was designed to improve the stability and rigidity of the structure, the system’s load capacity and its overall seal.

4 Thermal/acoustic insulation: insulating panels in thermobonded polyester fibre (supplied on request)

5 Impact noise insulation: multilayer backing membrane made of reticulated polyethylene and rubber (supplied on request)

Types of Support Structure

Different types of load bearing structure are possible by combining the various parts based on the load bearing needs and the layout of services and cables. Marazzi Engineering has focused on the development of high-performance solutions that have helped it expand the variety normally available on the market:

The TKS structure (no stringer): consisting of pedestal with 8-spoke radial head, where the panels are placed directly; a plastic gasket is fitted for less noise. Since there are no stringer, the columns in this type of structure are bonded to the sub-floor slab with specific glue.

The TKL structure (with stringer): the 8-spoke radial head pedestal are shaped so the 28 x 18 mm C-section stringer can be snapped into place. The snap-fastening instantly forms a solid link between the parts and speeds up the installation. Diagonal reinforcement stringer can also be added, if necessary, thanksto the special shape of the head.

The TKM structure (with medium stringer): pedestal with 8-spoke radial heads, shaped so the 28 x 38 mm C-section load-bearing stringer can be snapped into place. Again, the head of the columns allows for the addition of diagonal reinforcement crosspieces.

The TKC Structure (with heavy, closed overhead passing stringer): the pedestal have a cross-head with screws to lock the load bearing stringer in place using pressure. The load bearing stringer, where the heads of the columns rest, have a 50 x 25 mm rectangular section and various lengths: the side frames are 1800 or 3600 mm.

Core of the Raised Floor

This is the central part of the raised floor and it can be of two basic types depending on the construction material:

• In wood and resin chipboard featuring high density and high mechanical strength, with nominal thickness of 38 mm (type L38). This material has excellent properties in terms of low weight, economy, and ease of handling; in addition, it is in the lowest formaldehyde release class (E1).

• In inert material (anhydrous calcium sulphate) reinforced with high strength cellulose fibre, with nominal thickness of 30-34 mm (type K30-K34). The physical-mechanical characteristics and absolute safety in terms of the release of volatile substances make this material the best product for raised floors.

• Marazzi Engineering also offers a third solution: the Encapsulated Panel. This type of panel (23/29 mm thickness) consists of a calcium sulphate core – reinforced with cellulose fibres or with wood and resin chipboard – encapsulated in a hot-galvanized steel sheet coating which, by means of a double fold at the edge, increases the load capacity. The encapsulated panel is a technologically advanced system with high mechanical strength. It is very light and tough and

supports self-laying floor coverings.

Surface Layer

The upper coating applied to the core comprises the floor surface and defines the floor’s aesthetic appearance. Marazzi Engineering can supply any material for this purpose, from the most classic to the most innovative: porcelain stoneware, resilient materials (rubber, linoleum, PVC), plastic laminates, natural stone or stone composites and real wood. Porcelain stoneware is the most suitable material for the panels’ surface finish thanks to its special resistance and excellent technical characteristics. Marazzi offers the widest range of porcelain stoneware surfaces that are perfectly suitable for the creation of raised floors, including in areas with heavy traffic.

Accessories

Accessories are available to interface the raised floor with its immediate surroundings and exploit its features fully.

These include:

• Indoor and outdoor ramps

• Indoor and outdoor steps

• Partition walls for sound-proofing, fire prevention or

air ducts

• Front curtain walls

• Grills and perforated panels for ventilation

• Panels with grommets for electric wiring and data

cabling

• Grommet hatches

• Raised or flush outlet boxes with electric sockets or

telephone points

• Expansion joints

• Suction caps for lifting the panels

• Lateral finishes with contrasting strip for connection

to the wall

• Structural Bridges

Marazzi offers the widest specific range for raised floors. Through aesthetic effects with a natural look, contemporary finishes and solid colours, you can combine material beauty and high performance. Coordination between surfaces gives aesthetic continuity between indoor and outdoor floor coverings, an essential advantage for spaces that require the highest design standards and visual coherence. From 10 mm-thick indoor surfaces to 20 mm-thick outdoor surfaces, Marazzi meets the needs of contemporary architecture with advanced

and versatile technical floor coverings.